Choosing a glass container that fits the varied needs of each customer is an easy task at juvasa.com, given the range and quantities of glass jars available. But when it comes to deciding on the type of seals for bottles, the task becomes tricky: what type of lids are best for jam? and for honey? and for pâté?

There are several methods of food preservation and ways to avoid altering its original characteristics (appearance, taste and smell).

For thousands of years, man has been looking for techniques to preserve his products: adding natural or chemical substances, refrigerating or applying heat by cooking food. Perhaps in another post we will be able to deepen the topic….

Clarifying concepts:

Pasteurization and sterilization are part of the techniques of food preservation by heat.

Both techniques consist of the thermal destruction of the microorganisms present in certain foods, in order to allow their preservation for a longer period of time. The difference basically lies in the heating time and temperature.

In pasteurization, a food is heated to a temperature of between 70 and 95 ºC in a water bath and allowed to cool.

The sterilization process is achieved in a pressure cooker, or an autoclave in an industrial setting, which can reach temperatures between 100 and 115 ºC, sufficient to destroy most microorganisms.

4 Guidelines for choosing the best method for your preserves:

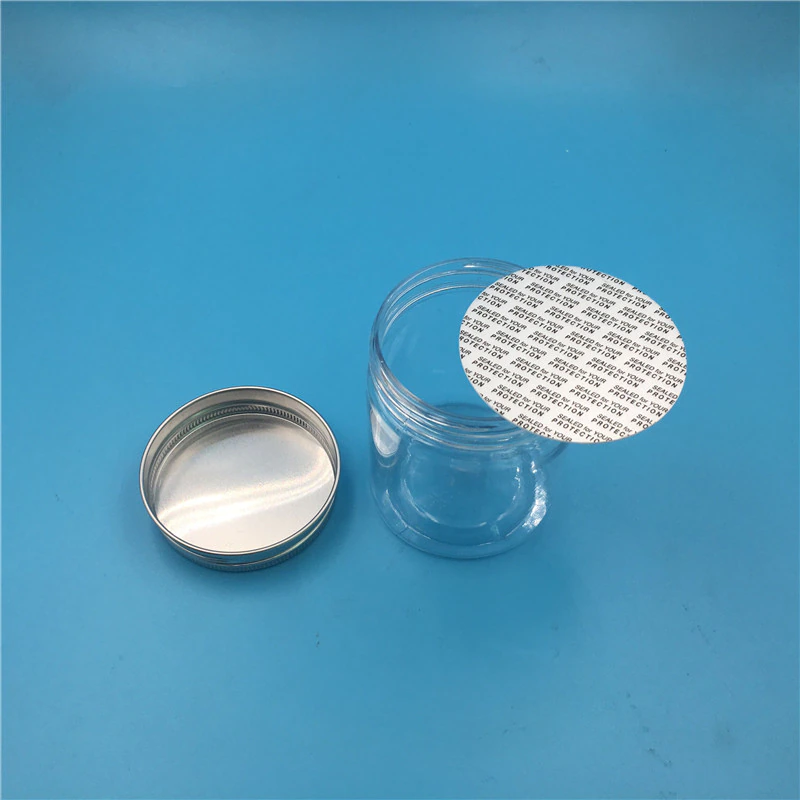

The cleanliness of containers and seals for bottles in an indispensable requirement for food preservation. It is necessary to sterilize glass jars, approved for food use, and to use first-use lids (under each container, in juvasa.com, you will find the appropriate lid); used, oxidized, deformed lids can cause problems of airtightness and deterioration of the product.

Canned food usually combines several methods to preserve food (natural substances/chemistry and cold/heat/cold thermal process), for example a jam is preserved thanks to sugar and pasteurization; a pickled gherkin preserve combines vinegar and pasteurization.

Not all foods respond equally to treatment. Certain factors can affect, positively or negatively, the efficiency of the process. The most representative is the acidity of the product, which determines the survival of the pathogen.

-Preserves composed only of vegetable ingredients and with a pH lower than 4.6 can be treated in a water bath, at a temperature not lower than 80ºC. In Juvasa.com you can find our pasteurizer, a large pot in stainless steel 18/10 of 30 liters of capacity with

Thermostat to mark directly the necessary temperature, maximum 100ºC;

Indicator light that controls the programmed temperature.

Timer to program the end of the cooking time, maximum 120 minutes.

Inner support to prevent the jars from breaking when the water boils.

Protection against overheating.

– Canned foods containing animal or dairy ingredients should always be treated in the pressure cooker (autoclave) at a temperature of not less than 120ºC.

In pasteurization it is advisable to work with low pH. Below a pH of 4.5 the bacteria cannot grow, hence the treatment can be milder and the organoleptic characteristics are not so affected.

For foods with a higher pH, treatment with a higher temperature is also necessary, as is the case with milk, vegetables, meat or fish.

- The cooking time should be sufficient so that the product in the center of the glass containers always receives the necessary heat. This depends on a number of factors for seals for bottles:

- Whether it is kept under pressure or not.

- The temperature of the food at the time it is introduced into the cooking water.

- The size of the container, the number of containers in the pot or the size of the pot.

- The nature of the food introduced (more or less liquid).